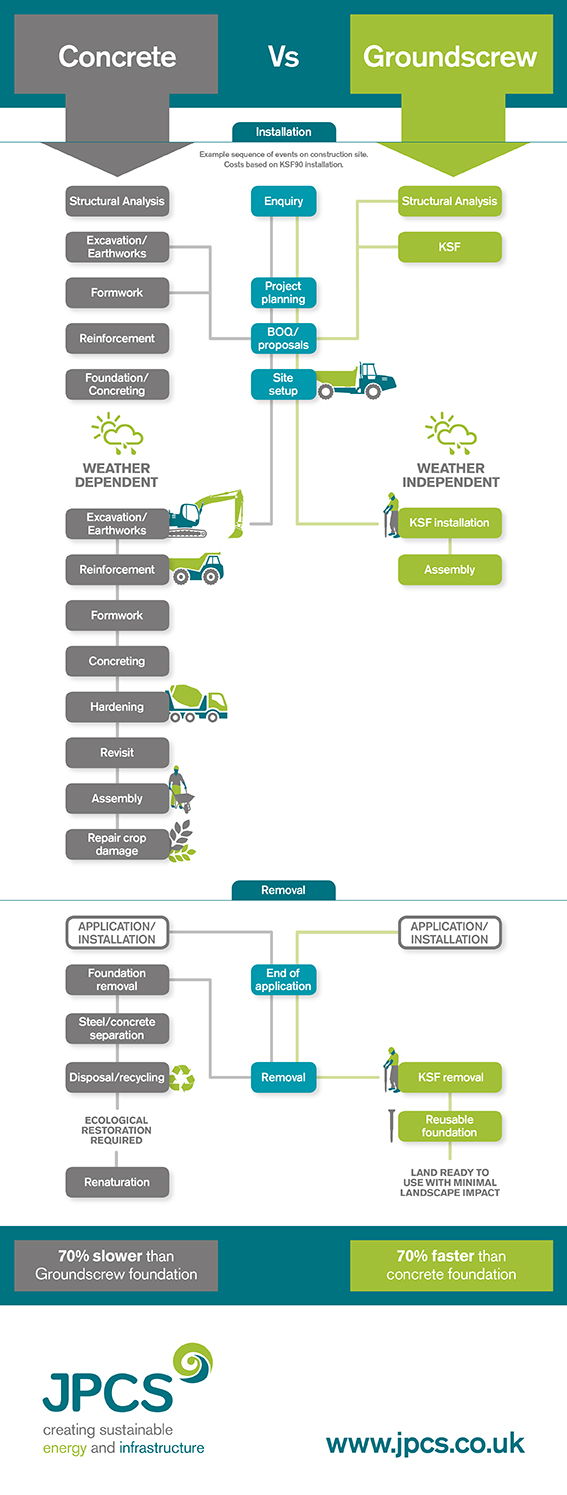

Ground screw vs concrete

The Krinner ground screw is an innovative alternative to concrete foundations. This infographic by Krinner UK’s installation partner JPCS, illustrates the difference between using our ground screw foundation and the use of concrete across a variety of applications.

Download a pdf version of the Ground screw Vs Concrete inforgraphic.

20mph project using ground screw is 'Highly Commended' by CIHT

A 20mph speed limit sign rollout in Warrington, which used the innovative krinner ground screw for 50% of the works, has been ‘Highly Commended’ in the North West Safety Project of the Year category, at the 2014 Chartered Institution of Highways & Transportation (CIHT) North West Branch Awards.

[Pictured L-R: Mark Tune (Warrington Borough Council), Ines Osborne (JPCS), Tom Cowie (Warrington Borough Council), and Jenny Neville, (JPCS)]

The project was delivered by Krinner UK’s exclusive installation partner, JPCS, and has already delivered a number of benefits, including 40% cost savings and delivery 6 months ahead of schedule with ground screw. The scheme was earlier shortlisted for ‘Best Practice’ and ‘Safety Project of the Year’ at the CIHT awards.

Jenny Neville, director at highway maintenance and civil engineering contractor JPCS, said: “We are delighted that this project has been ‘Highly Commended’ at this year’s North West CIHT awards. A big well done to the teams at Warrington Borough Council and JPCS, who have worked so well together to make the project such a huge success.

“The innovative ground screw concept, the hard work of our talented teams on the ground, and our partnership’s pioneering approach to the 20mph speed limit rollout has already delivered benefits to the council and the local community.

“As well as reducing costs by £50k – equating to 40 per cent of estimated costs in phase one alone – using ground screw has enabled the partnership to stay 6 months ahead of schedule, and we now expect all 20mph speed limits to be implemented by the end of 2014.”

Ground screws help to deliver road safety in Warrington

Krinner ground screws are being used as part of a road safety drive in Warrington, to install new 20 mile-per-hour speed signs across the borough.

Warrington Borough Council is rolling the 20 mile-per-hour programme following an 18 month long pilot scheme and has appointed Krinner UK partner, JPCS, as the installation contractor.

Krinner ground screws will be used as the foundation for around 50% of the signs, to enable more flexibility across the speed zones, as well as delivering savings of around 30% against traditional concrete solutions. An alternative to traditional concrete bases, the ground screw is faster and safer to install, allowing the signs to be moved from site to site easily, as required.

Councillor Linda Dirir, executive board member for highways, transportation and climate change at Warrington Borough Council, said:

“This new scheme will have huge benefits for the town and we hope everybody will get behind it. Not only does it mean increased safety for road users and residents, but with lower speeds it gives residents the confidence to use other modes of travel and encourages walking or cycling. People can also enjoy the health and wellbeing benefits.

“The 20 mile-per-hour roll-out will also help us to work towards our environmental targets to reduce emissions and cost by promoting awareness and encouraging the adoption of other means of travel.”

Rosie Shanks, director at JPCS, said: “It’s very encouraging to see that road safety is at the top of the agenda in Warrington. Figures from the Transport Research Laboratory have shown that lowering urban and residential speed limits to 20 miles-per-hour can decrease child pedestrian accidents by up to 70 per cent so we’re really pleased about the opportunity to contribute to making roads safer in Warrington – something we are passionate about.

“We’ve been working with Warrington Borough Council to develop a cost effective solution which could save up to 30 per cent on costs, as well as halving the time spent on site, as it removes the need for excavation and concreting. This means that the new safety zones can be in place quickly, safely, and with as little disruption to residents as possible.”

Christmas closure

Please note that Krinner UK will close for the Christmas holiday on Monday 23rd December at 5pm. Our offices will re-open on Thursday 2nd January at 8am.

We would like to wish you a very Merry Christmas and a Happy New Year.

Ground screw as an innovation in rail

Many of the UK’s railway stations have either undergone or are currently undergoing facelifts – and let’s face it, it’s about time. This post discusses why ground screw could be solution to refurbishment challenges in rail.

With over 2,500 stations on the national railway network, the majority of which over 100 years old, not to mention around 2.6 billion passengers passing through every year, the facilities at many stations are simply no longer fit for purpose.*

The UK Government has put in place a £37.5 billion plan to improve Britain’s railways, which is a fantastic opportunity not only for the construction and maintenance industry, but also for Train Operating Companies (TOCs).

Yet the high volume of trains and passengers can present challenges. Ensuring the safety of all passengers and station employees, keeping disruption to a minimum, restricted site access, and possessions with limited working windows must be considered when undertaking refurbishment works in the rail environment.

As well as buildings and platform surfaces, station furniture, including benches, shelters, ticket machines and bins, also need to be maintained and upgraded.

This is where ground screw comes in. A concrete-free foundation system, it is perfect solution for the railway refurbishment market. Ground screw is a robust foundation system and a sustainable alternative to traditional concrete for modular platform extensions, platform and track furniture, and signage. The system removes the need for excavation and concreting, so where you would usually cast small concrete pads ground screw can be used instead.

With the previous Form A and Form B approval for use as a ground foundation in location cabinet stagings, small ground signals, and small trackside signage, ground screw allows signs, fencing, benches and other structures to be positioned quickly and easily – a significant advantage during possessions. Because it reduces time on site, it also minimises disruption and improves safety on site.

For more information, please visit our rail section.

——

* Figures from 2009 report on Better Railway Stations http://assets.dft.gov.uk/publications/better-rail-stations/report.pdf

Why the sun is still shining for solar pv

THE window of opportunity for solar energy development is still open to farmers and landowners in the UK, particularly in the South West of England, according to ground mounted solar construction specialist and Krinner UK installation partner, JPCS.

Following reductions in both the Government’s Feed-in-Tariffs (FITs) and Renewable Obligation Certificates (ROCs) payments, many would-be developers have mistakenly believed solar farms are no longer viable, but JPCS is keen to ensure landowners are aware that positive returns will still be generated.

With 70 solar farms in the South West running at a combined capacity of 290MWp, JPCS believes there are also many undeveloped opportunities, including over 200MW in Cornwall with approved planning, which could double this figure in five years.

Government reports show that between June 2011 and June 2012 there was a 27 per cent increase in the amount of renewable electricity generated from solar energy in the UK. This figure is set to grow even more this year and, as the South West is one the sunniest areas of the UK, future progression is going to be driven by this region.

Peter Shone, managing director at JPCS, said: “Solar energy was not included as part of the Government’s top 10 renewable energy sources in 2011, but in less than 12 months it is predicted to have taken the fourth spot for renewable electrical energy generation in the UK.

“However many landowners are still hesitant about investing in ground mounted solar because of the initial installation cost. That’s why we have developed our foundation products and mounting frames, as well as our construction methods, to provide significant reductions in solar build costs. In particular the innovative ground screw foundation system, which provides notable installation benefits.”

“The reduced installation costs mean farmers, landowners and scheme developers can still generate substantial, above-market, returns from ground mounted solar.”

The Krinner ground screw is a robust and sustainable alternative to traditional concrete foundations. The system removes the need for excavation and concreting, reducing construction costs and times.

The Krinner ground screw foundation has proved highly effective: sufficiently flexible to survive high wind loads and work in extreme temperatures and adverse geological conditions, with the advantages of rapid installation and minimal maintenance. JPCS has completed more than 55MWp of solar PV construction using the ground screw foundation, with over 30MWp constructed in the first quarter of 2013 alone, in less than 16 weeks, and in some of the worst weather conditions in the last 50 years.

Renewable energy has long term public support in the UK

A major new survey by the Department of Energy and Climate Change (DECC) has revealed that public support for renewable energy has increased over the past year.

Carried out last month, the Public Attitudes Tracking Survey, now in its fifth wave, surveyed around 2,000 people, confirming a rise in support for renewable energy from 79 per cent to 82 per cent. The survey has revealed that solar power remains the most popular renewable technology, with support rising to 85 per cent from 82 per cent last June.

A sustainable alternative to concrete, Krinner’s ground screw foundation has made a significant contribution to renewable energy targets in the UK. Over 48,000 krinner ground screws has been the foundation of choice for the installation of 55Mwp of solar energy over the past two years, mounting 185,000 solar PV modules across 235 miles of aluminium rails, including some of the UK’s largest solar farms.

As well as renewable energy, the ground screw foundation is also a sustainable solution for a number of applications, including infrastructure.

Ground screw foundation supports over 50MWp of solar energy in the UK

The Krinner ground screw foundation has been used to install over 50MWp of ground mounted solar energy in the UK.

This landmark has been achieved together with Krinner UK’s installation partner, JPCS, with over 30MWp installed in the first quarter of 2013 alone, including the UK’s largest solar farm, at the time at 5MWp. Using over 48,000 Groundscrews, ground screw has provided the foundations for around 58 miles of frames and 235 miles of aluminium rails, to mount 185,000 solar PV modules, which is the equivalent surface area of 1400 tennis courts.

The 55MWp would have the capacity to power over 92,000 homes, boil 26,500 kettles and run 4.8 million low energy light bulbs.

The ground screw foundation is a robust and sustainable alternative to traditional concrete foundations, removing the need for excavation and concreting. Other applications for the ground screw foundation include signage, timber construction, fencing.

Sharing ground screw best practice worldwide

(Pictured above L-R: Michael Krinner (founder), Hans-Jürgen Sauter (CEO), and Peter Shone, managing director of JPCS).

Krinner UK’s installtion partner, JPCS, has been sharing ground screw best practice with worldwide partners at this year’s Krinner International Sales Summit.

The summit, held in Abu Dhabi in January, brought together Krinner ground screw partners from Czech Republic, France, UK, North America, Canada, MEA, Asia and Japan. Michael Krinner (founder), Hans-Jürgen Sauter (CEO) and Peter Hamer (head of Krinner Groundscrew) were present from Krinner’s headquarters in Germany.

Peter Shone, Managing Director of JPCS, who represented Krinner’s presence in the UK said: “Getting together with Krinner partners worldwide was a great experience. I am proud to be part of a team who embrace simplcity and innovation.”

Presentations at the summit included sales development and forecast, investment, and markets for the Krinner ground screw. JPCS’ shared some of its secrets for success in using ground screw, including employment of experienced contractors, using the correct equipment, and involvement at earliest stage of the project.

Krinner ground screws provide foundation for award winning project

A 50 kWp solar PV project in Bodmin built on krinner ground screws has won an award for the ’The Best Large Scale Renewable Energy Scheme’ in Cornwall at the Cornwall Sustainability Awards earlier this month.

A 50 kWp solar PV project in Bodmin built on krinner ground screws has won an award for the ’The Best Large Scale Renewable Energy Scheme’ in Cornwall at the Cornwall Sustainability Awards earlier this month.

The installation was completed in August 2011, despite challenging ground conditions, with 88 krinner ground screws used as the foundation for the scheme.

Author and explorer Robin Hanbury-Tenison’s Cabilla Manor has generated around 45,000 kWh worth of energy in the first year alone.

The 10th awards event was held in Falmouth, with over 200 guests attending to celebrate the achievements of businesses in the region.

The Cornwall Sustainability Awards are organised by the Environment Agency and Cornwall Council and aim to encourage, reward and gain recognition for some of the excellent work businesses in Cornwall and the Isles of Scilly are doing to improve their sustainability.